|

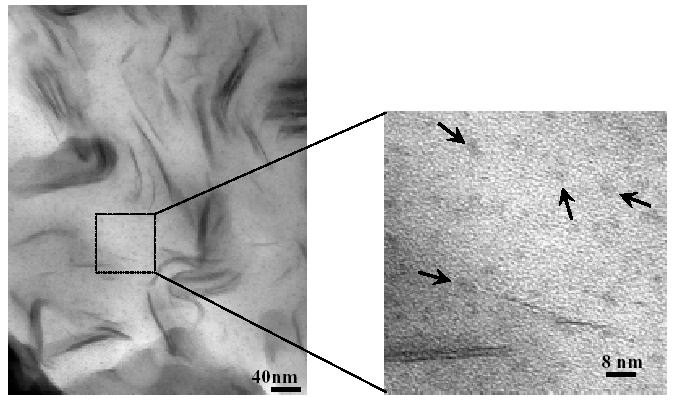

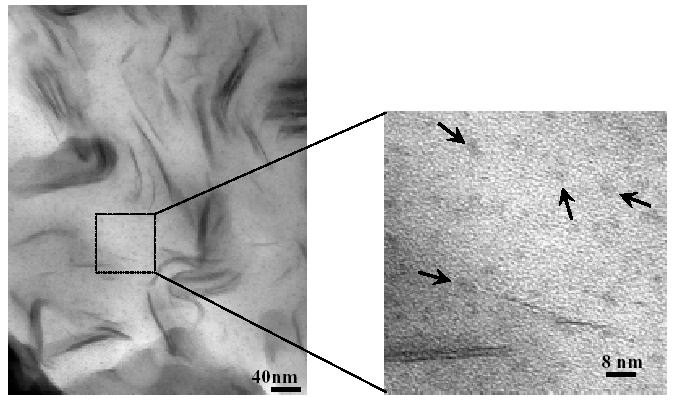

The highly neutralized ionomer-based nano-composite materials were prepared

via direct melt processing using zinc oxide (as a neutralizating agent)

and organically modified clay. The nano-structure was characterized using

wide-angle X-ray diffraction analyses, transmission electron microscopy

observations and rheometry. The dispersed organo-clay acted as catalytic

sites for the neutralization. From TEM analyses, the nano-sized ionic aggregates

with a domain size of approximately 2 nm were randomly arranged in the

ionomer matrix. The calculated aggregates density for the nano-composite

was 0.08-0.15 nm-2.

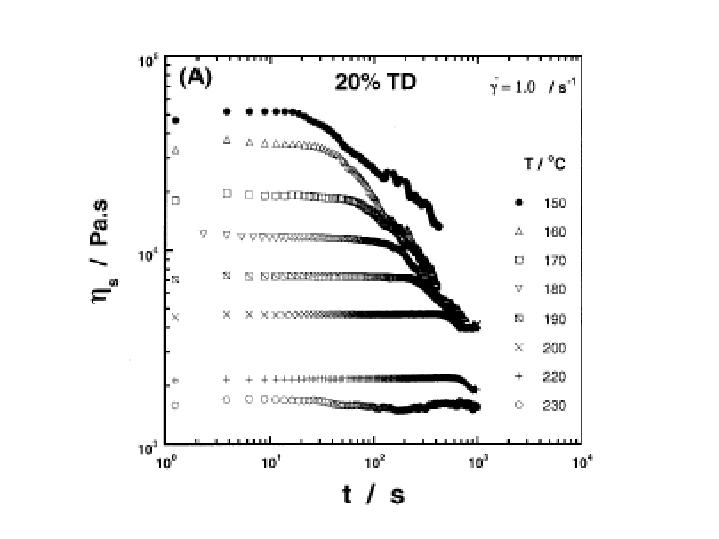

The temperature-dependent relaxation process observed in the viscoelastic

measurements was somehow affected by the presence of the silicate layers,

whereas it was strongly affected by the specific interaction via ionic

aggregated domains.

Composite Part A, 2008, 39, 1924-1929 |

|

|

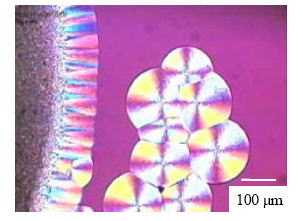

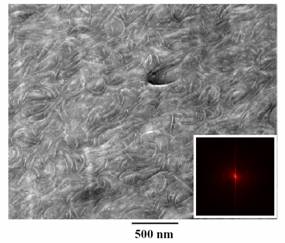

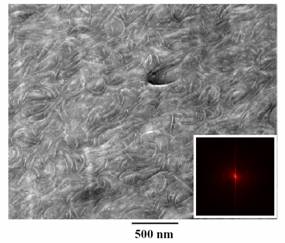

To

understand the effect of the montmorillonite

(MMT) particles on the

crystallization kinetics and crystalline morphology of nylon 6 upon nano-composite formation, we have characterized the crystallization behaviors by

using light scattering, wide-angle X-ray diffraction (WAXD), transmission

electron microscope (TEM) and rheological measurement. The

correlation between the nucleating effect and the growth mechanism of the

different polymorphism (g-phase) of nylon 6 in the nano-composite

(N6C3.7) was probed. N6C3.7 exhibited g-phase

crystal due to the nucleating effect of the dispersed MMT particles into the

nylon 6 matrix throughout the whole Tc

range (= 150-215 °C). The lamellar growth of the g-phase

crystal took place on both sides of the dispersed MMT particles. In comparison

between the temperature dependence of the characteristic relaxation time and

the crystallization time, the lamellar growth of the g-phase crystal has been discussed. The stable growth

of the g-phase was strongly disturbed at at low Tc range (= 160-190 °C) due

to the lack of time for crystallization.

Polymer,2009, 50, 4718-4726

|

|

|

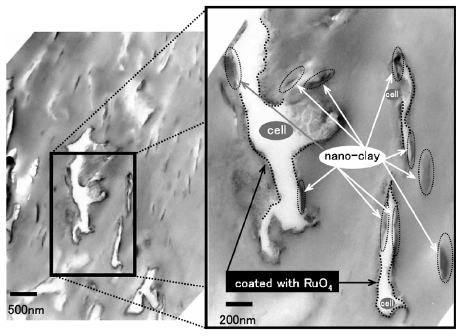

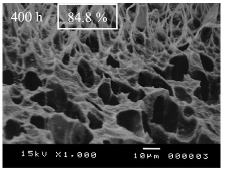

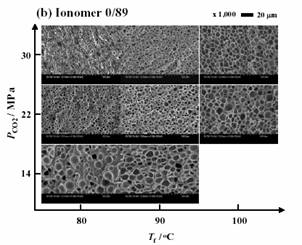

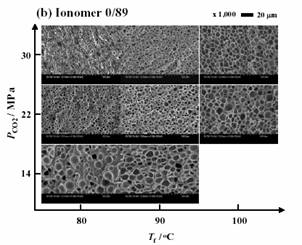

Via a batch process, the foam processing of polyethylene-based

ionomers having two different degree of the neutralization has been conducted

using supercritical CO2. The cellular structures obtained from

various ranges of foaming temperature-CO2 pressure were investigated

by using field emission scanning electron microscopy. For comparison, the

corresponding nano-composite also has been examined. The ionic cross-linked

structure in the ionomer exhibited significant contribution to retard the cell

growth and coalescence of cell, especially in ionomer having higher degree of

the neutralization. For nano-composite foaming, experimentally, nano-clay

particles led to an increase in cell density after foaming. However, the

dispersed nano-clay particles did not act as nucleating sites for cell

formation. The competitive phenomenon between the cell nucleation and the cell

growth including the coalescence of cell was discussed in the light of the

interfacial energy and the relaxation rate as revealed by the modified

classical nucleation theory and rheological measurement, respectively.

Composites: Part A, 2009, 40, 1708-1716

|

|

|

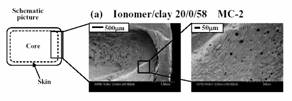

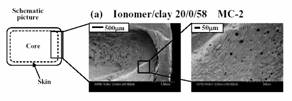

To understand the correlation between

foamability and melt rheology of polyethylene-based ionomers having different

degree of the neutralization and corresponding nano-composites, we have

conducted the foam processing via a batch process in an autoclave and

microcellular foam injection molding (FIM) process using the MuCell(R) technology. We have discussed the obtainable morphological properties in both foaming processes. All cellular structures were investigated by using field emission scanning electron microscopy. The competitive phenomenon between the cell nucleation and the cell growth including the coalescence of cell was discussed in the light of the interfacial energy and the relaxation rate as revealed by the modified classical nucleation theory and rheological measurement, respectively. The FIM process led to the opposite behavior in the cell growth and coalescence of cell as compared with that of the batch process, where the ionic cross-linked structure has significant contribution to retard the cell growth and coalescence of cell. The mechanical properties of the structural foams obtained by FIM process were discussed.

Mater. Sci. Eng. C, 2010, 30, 62-70

|

|

|

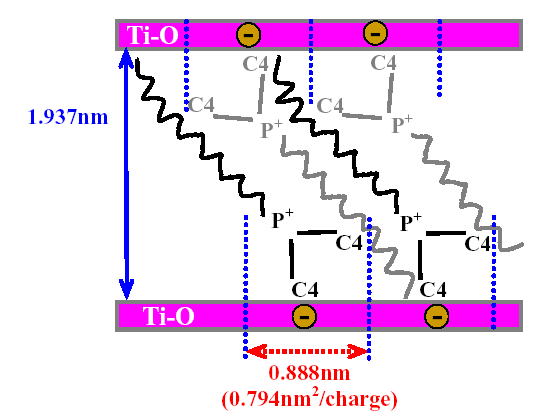

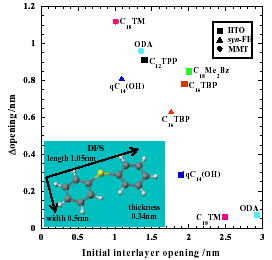

To

understand the effect of

confined space (interlayer space in montmorillonite (MMT)) on the nonisothermal

ordering transition

(chain packing) kinetics and disorder

transition (chain melting) behavior including the conformational changes of the chain segment of

the cationic surfactants, we have characterized MMT modified with dioctadecyl dimethylammonium

(DC18DM) ions (MMT-DC18DM) using temperature-modulated differential

scanning calorimeter (TMDSC), wide-angle X-ray diffraction (WAXD) and Fourier

transform infrared spectroscopy (FTIR) technique. For MMT-DC18DM,

the chain conformational disorder-order phase transition took place during the cooling

process. The transition peak was much broader and it appeared at lower

temperature (Tc) when

compared to the crystallized dioctadecyl dimethylammonium bromide (DC18DM-Br),

as a reference

In MMT-DC18DM, the

formation of gauche conformers was enhanced and the chains were not as densely

packed as in crystalline DC18DM-Br. The normal crystallization took

place in the bulk during the nonisothermal crystallization of DC18DM-Br.

The confined ions (DC18DMs) in one or two dimensional order

contributed to the nonisothermal chain packing for a higher cooling rate of

5.0-20.0 °C/min. The observed chain packing in confined space at different Tc ranges (cooling rate >

5.0 °C/min) could be explained by much lower energy barrier.

Appl. Clay Sci., 2010, 48, 73-80

|

|

|

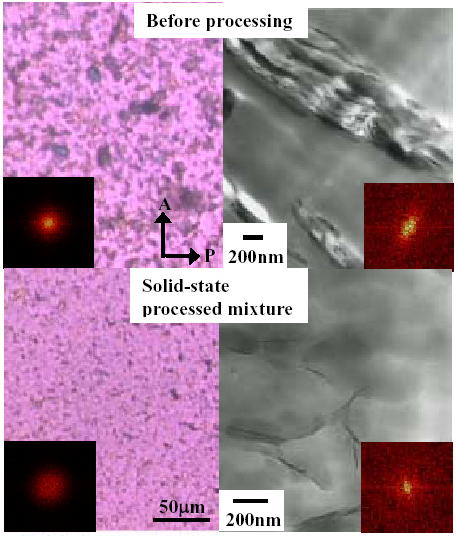

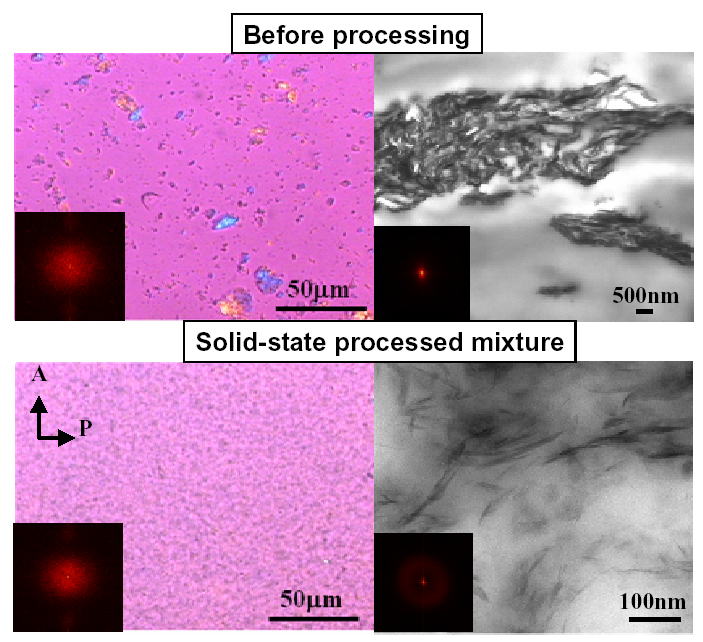

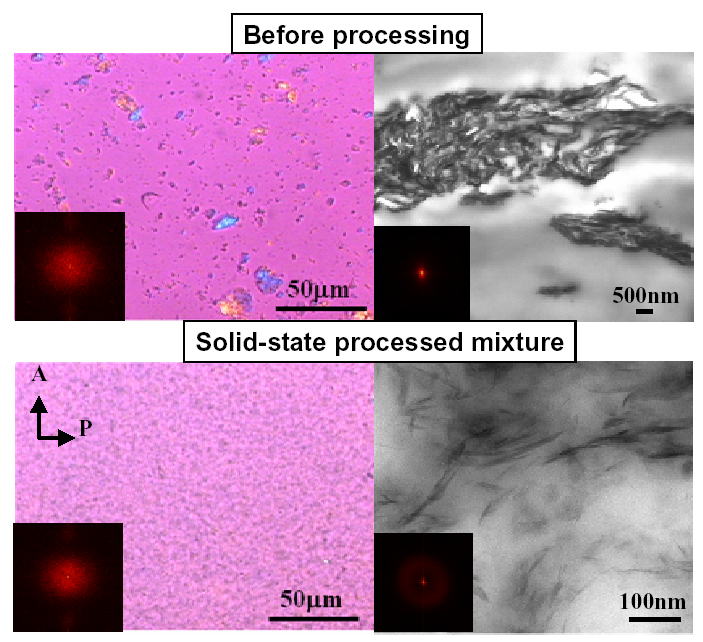

Solid-state processing for the preparation of polypropylene (PP)-based

nano-composites having finely dispersed layered fillers was conducted.

The mixture of PP and organically modified layered filler (OMLF) (95:5

wt./wt.) was subjected to the processing using alumina mortar heated 65

°C, below Tm of PP (i.e., PP is still at the solid-state), and ground

for 8 h before melt compounding. On X-ray diffraction, the d(001) peak

of OMLF was broaden and peak position shifted slightly. The mixture prepared

by solid-state processing exhibited disorder and delaminated layer structure

with the thickness of 3-7 nm into PP matrix through TEM observations. On

the contrary, nano-composite prepared by melt compounding at 180 °C for

3 min (without solid-state processing) showed the large stacked silicate

layers in the PP matrix. Furthermore, instead of using alumina mortar,

we carried out solid-state processing using internal mixer. X-ray diffraction

pattern and TEM observation exhibited similar results. The solid-state

processing led to delaminate of the silicate layers and attained the discrete

dispersion.

Polymer, 2010, 51,4238-4242

|

|

|

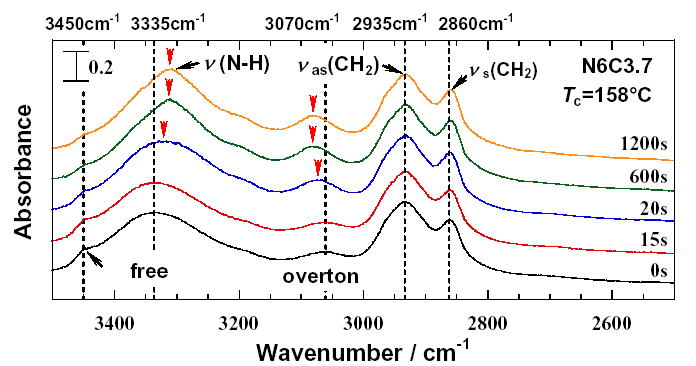

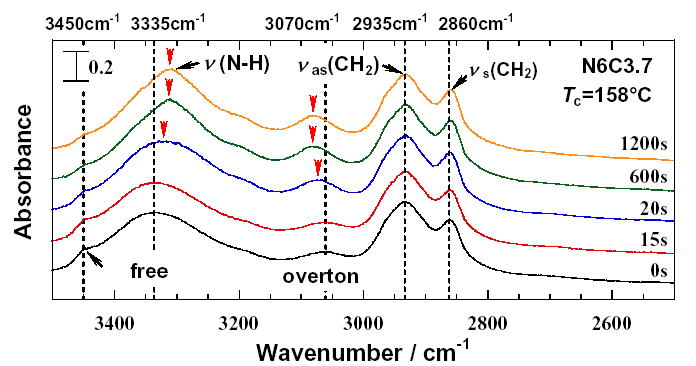

Via time-resolved FTIR, we examined the real-time investigation of the

structural change in molecular chain of nylon 6 during crystallization

of neat nylon 6 and the corresponding nano-composite (N6C3.7) having fully

exfoliated structure. The neat nylon 6 predominantly formed alpha-phase

in the crystallization temperature (Tc) range of 155-195 °C. For N6C3.7

crystallization at low Tc range of 150-168 °C, where the network structure

formed by the dispersed clay particles still affected chain folding of

nylon 6, the formation of the gamma-phase was dominant. The crystallization

took place so rapidly (less than 1s) without induction time of crystallization.

At high Tc range (=177-191 °C), the stable growth of the alpha-phase crystal

coexisting with gamma-phase occurred in N6C3.7 crystallization. The growth

mechanism in the subsequent crystallization processes (amides III alpha

and III gamma) were virtually the same in both N6C3.7 and neat nylon 6.

Polymer, 2010, 51,5585-5591 |

|

|

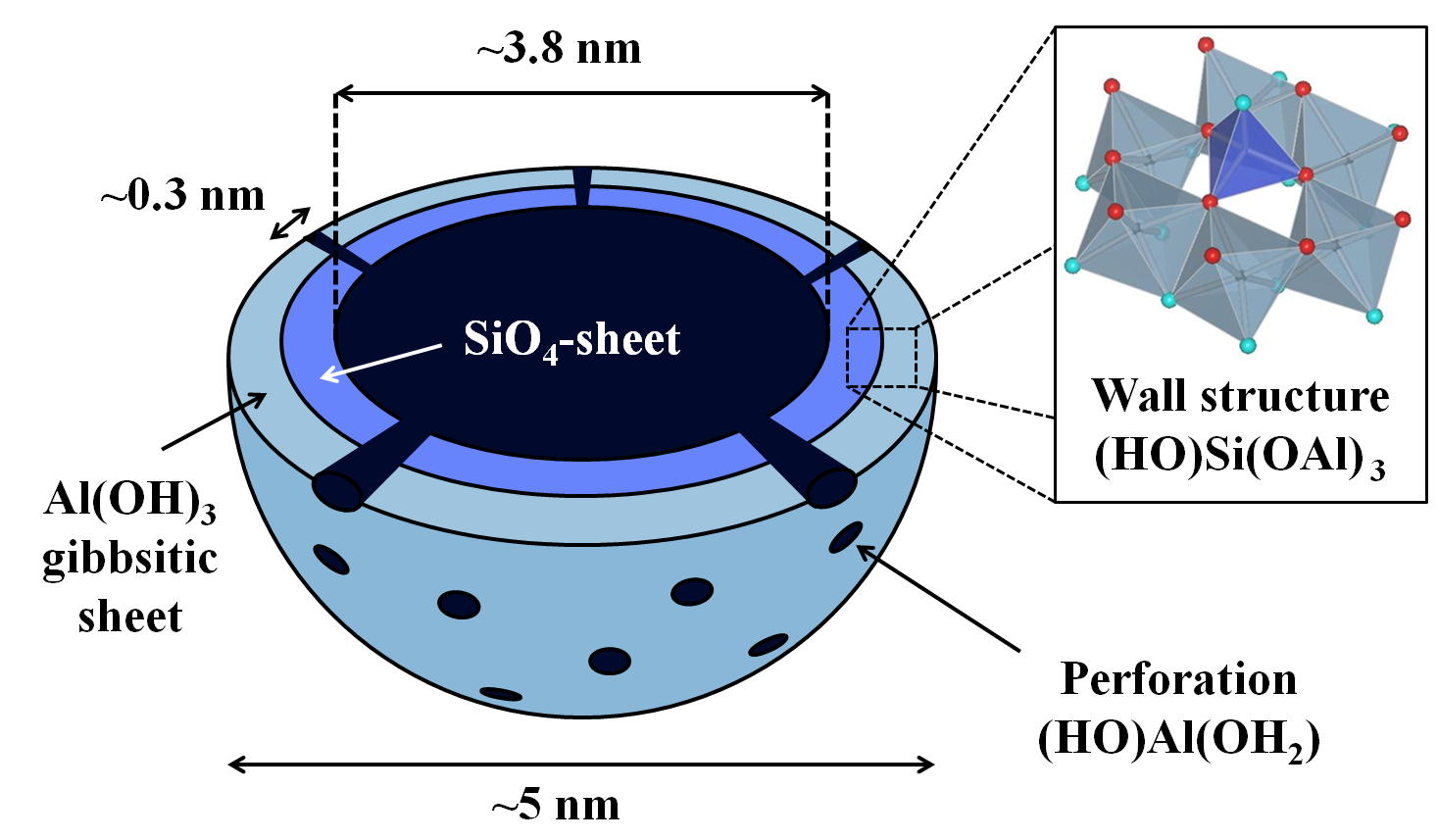

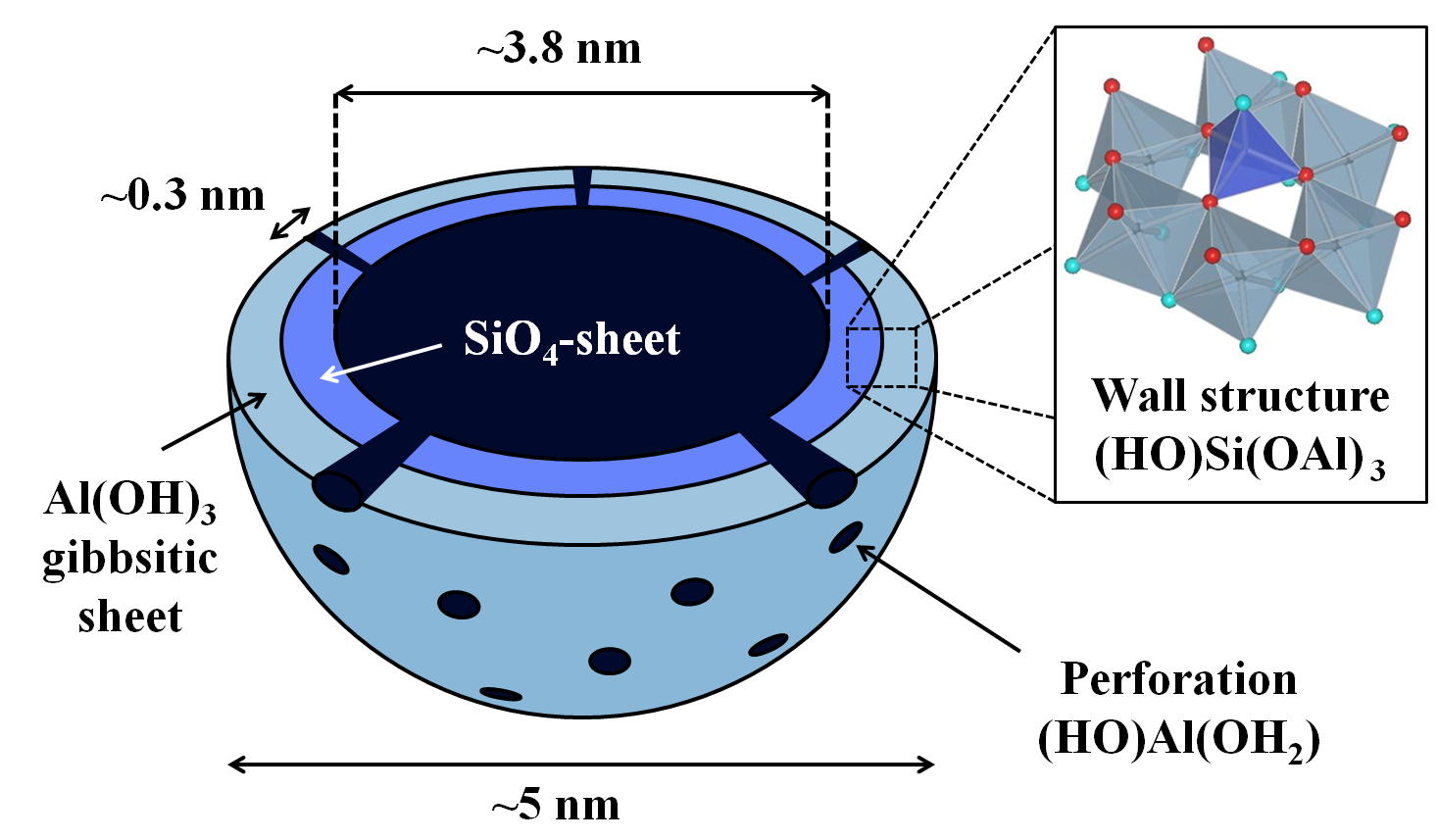

We synthesized three allophanes from precursors by a hydrothermal reaction at 100°C for 48h. The precursors were formed from the solutions of Na4SiO4 and AlCl3?6H2O at different Si/Al molar ratios (0.5, 0.75, 1.0). The nanostructure of the synthetic allophanes was compared with that of a natural allophane from New Zealand by using X-ray diffractometry, energy dispersive X-ray spectroscopy, Fourier-transform infrared spectroscopy, thermogravimetry/ differential thermal analysis, 29Si and 27Al magic angle spinning (MAS) nuclear magnetic resonance (NMR), field emission electron microscopy, and pore-size distribution based on the Cranston-Inkley method. The propensity of the allophanes to adsorb adenine and adenosine-5’-monophosphate (5’-AMP) was assessed by batch experiments. The adsorption data were fitted by the Freundlich equation and the adsorption parameters were discussed in relation to the properties of the natural and synthetic allophanes. The adsorption capacity (Kf) of the natural allophane for 5’-AMP was three times that for adenine. The average Kf value of the three synthetic allophanes for 5’-AMP was more than twice that of the natural allophane, possibly due to the higher purity of the synthetic allophanes.

Key words: allophanes, nanoparticles, adenine, 5’-AMP, adsorption.

Appl. Clay Sci., in press, 2011

|